We will continue to pioneer the technologies the world needs to achieve the airlines sustainable targets

Welcome to a better aviation future.

SATC

Sustainable Aviation Technology Consultancy

Reuse

Repair

The waste of high value aerospace-grade materials is one of the biggest losses in aviation. Reusing these valuable and scarce materials is a challenge for sustainable aviation technology. SATC support the airlines in the development of safe and sustainable management of circularity of components and aircraft in the aviation sector. SATC will continue to pioneer the technologies the world needs to achieve the airlines sustainable targets.

Repair

We support the airline industry with reducing their maintenance costs by making use of innovative authorized alternate repairs instead of replacing parts (Repair). We stimulate Repair Development to improve circularity of components and aircraft in the aviation sector (Redesign). When repairs are removed or lacking in the manuals, the airline customers are forced to replace parts instead of being able to repair these parts. SATC supports customers in the process to source or develop authorized repairs. SATC is able to support implementation of these authorized repairs in the customers maintenance documentation/program.

Why?

Environment & Sustainability targets

The International Air Transport Association (IATA) recognizes the need to address the global challenge of climate change and adopted targets to reduce CO2 emissions from air transport. These targets focus on improved fuel efficiency and to lower emissions.

The Maintenance Repair Organization’s (MRO) can contribute to these targets for more sustainable aviation. SATC is committed to a sustainable future and supports airlines, MRO’s and OEM’s to prevent waste and pollution, keep products and materials in use, by offering authorized repairs instead of replacing parts.

Circular Economy will save maintenance cost for the airline industry

The airline industry can save yearly millions of dollars on their maintenance costs by repairing and reusing parts instead of replacing these parts for new. We support the airlines in the development of safe and sustainable management of circularity of components and aircraft in the aviation sector.

How can we help?

Repair Development

- Together with our customers we can determine the High Impact parts. For these parts we will provide authorized alternatives. The repair development strategy will be presented in Repair Development Plan

- We work closely with (the customers) engineers for the development, approval, implementation and maintenance of new and existing repair schemes or alternate sources of supply for component parts.

SHOW MORE

Support

We can also support with the implementation of the repair development plan:

- Develop and industrialize new repairs/process technology to be implemented in the customers repair strategy.

- Action plan for the customers engineering department to implement these options into the customers maintenance programs

- Work with engineering department for substantiation of sourced repairs/process qualifications/certifications

- Coordinates the initial stages of the developmental process, as well as, required design changes in existing business units (based on six sigma principles)

- Coordinate the vendor qualification process, including completion and evaluation of customer and/or regulatory compliance programs.

- Negotiations with the customers suppliers and lessors/leasing companies

- Calculate the yearly cost savings

About us

Sustainable Aviation Technology Consultancy (SATC) & Mirjam Hooimeijer

After many years of experience at KLM Engineering & Maintenance and Chromalloy I decided to use my experience and knowledge to support the technical airline industry with their repair development ambitions. I believe we should support our customers to make use of innovative authorized repairs instead of forcing them to replace high value parts. I also believe repairing parts instead of replacing them will have a positive influence on the airlines and world sustainability targets for reducing CO2 emissions.

I use my experience from my time as a design engineer, quality assurance manager, fleet manager, purchasing manager, regional account manager and business development manager to design a repair development plan for the customer. Not only to safe on their maintenance cost, but also to contribute to a better sustainable technical aviation world.

Experience/Cases/projects

Assets trading and strategy (CF6-80C2, B747-400, APUs)

Business Developments:

- Regional account manager engine repair shop (CFM56 program)

- Purchasing manager (Vendor management and Repair Development plan APU repair shop)

- OEM negotiations

- Implementation Tear Down line

Engineering:

- Fleet Engineer

- Quality Assurance Manager

- Design Engineer Systems

- Implementation of DOA (Design Organization Approval)

SATC Blog

The engineering pioneers making aircraft greener

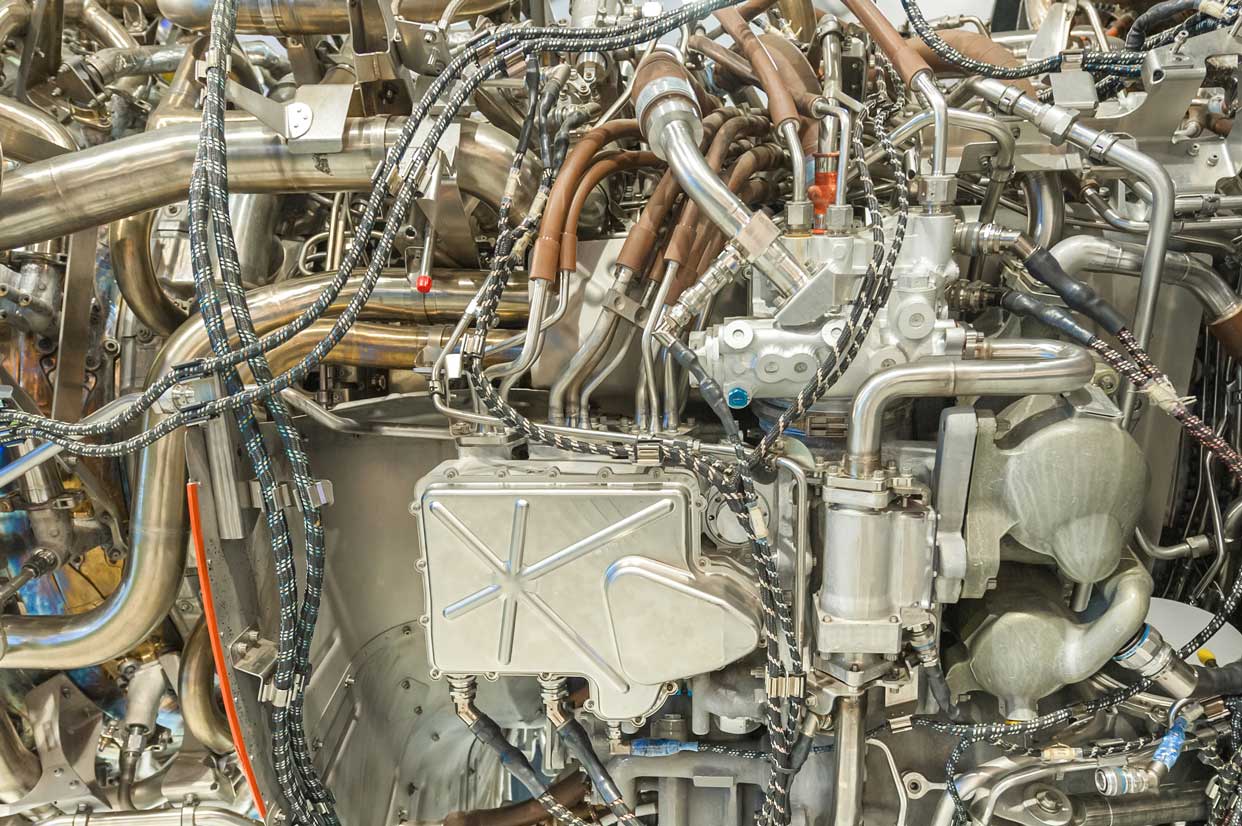

OEM’s like General Electrics (GE) and Safran (together through CFM International) and Pratt & Whitney Canada (PWC) have invested in technologies to make their engines cleaner, quieter, and more efficient. The less fuel an aircraft burns, the less impact it has on...

Ready for a circular transition in aviation?